The Angelantoni Group has always been a center of innovation, through its collaboration with universities and research institutes, which has led to the design and manufacture of cutting-edge products in various fields of application and the registering of a large number of patents.

Since its founding in 1932, the company has faced and won many challenges, focusing on offering innovative solutions and providing customers with ingenious products and bespoke services, helping them in the best manner possible.

Founder Giuseppe Angelantoni was a staunch supporter of innovation and research, such that he developed and created 16 patents after World War II alone.

- University of Firenze

ACS project aimed at understanding the factors that enable growth in services.

- Electrochemical Energy Storage and Energy Conversion Division of the Center for Solar Energy and Hydrogen Research, Ulm (Prof. Garche)

ACS technology scouting of lithium batteries, focusing particularly on safety aspects

- Roma3 University

Collaboration for developing the Turboalgor turbocharger

- University of Perugia

Collaboration with the CIRIAF for the LCA of the Turboalgor kit

- Roma3 University

Collaboration for the preliminary analysis and consultancy in the development of the high efficiency piston compressor with triple suction (Vireco)

- University of Salerno

ALS collaboration project for the 180°C freezer, the energy-efficient 80°C freezer, and the Plasma Frost

- University of Parma

Kenosistec collaboration for the development of photovoltaic panels as part of the Arendi project

- Sapienza University of Rome

ACS technology scouting of lithium batteries

- University of Perugia, Faculty of Engineering, Industrial Engineering Department

Energy savings in Environmental Simulation Testing: Optimization of Critical Operating Parameters of an Innovative model of Climatic Chamber – study for better defining and improving the energy-saving performance of the Flower® chamber

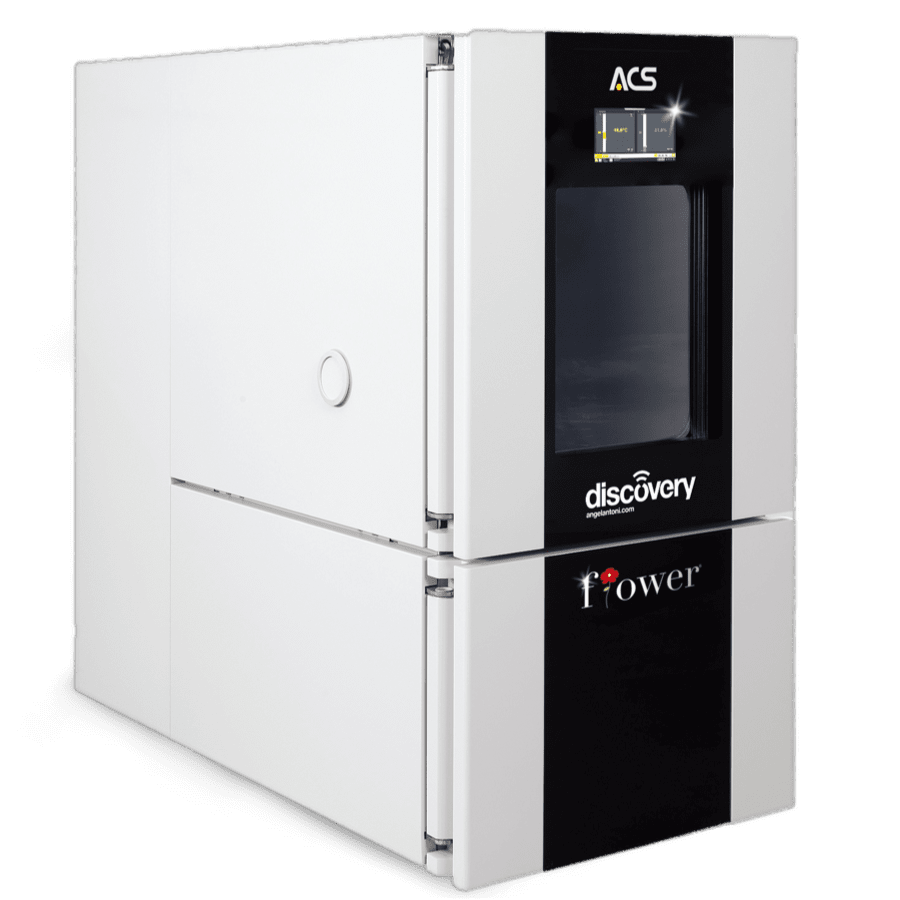

Flower®: the energy-saving climatic chamber

Since January 2007, ACS has been offering its customers the innovative Flower® environmental test chamber, the result of the company’s Research & Development efforts connected with the principles of environmental sustainability and eco-friendly development.

Up to 70% reduction in energy consumption is possible during the stabilization stages, thanks to a patented system consisting of an inverter that controls the compressor rotation speed and allows it to adapt its power to different work needs, and to a “cold accumulator” for increased cooling efficiency.

MyKratos™ Control System | MyAngel24™ remote assistance

In late 2014 ACS launched the first climatic chamber capable of meeting the new needs of Industry 4.0 for integrated, interconnected and communicating machines.

The MyKratos™ software, presented with the new Discovery My chamber line, is the ACS chamber management software, installed in the machine with built-in hardware that allows the controlling and management of the chamber functions through any type of connection (Wi-Fi, Ethernet, mobile network).

MyKratos™ includes the MyAngel24™ remote assistance system.

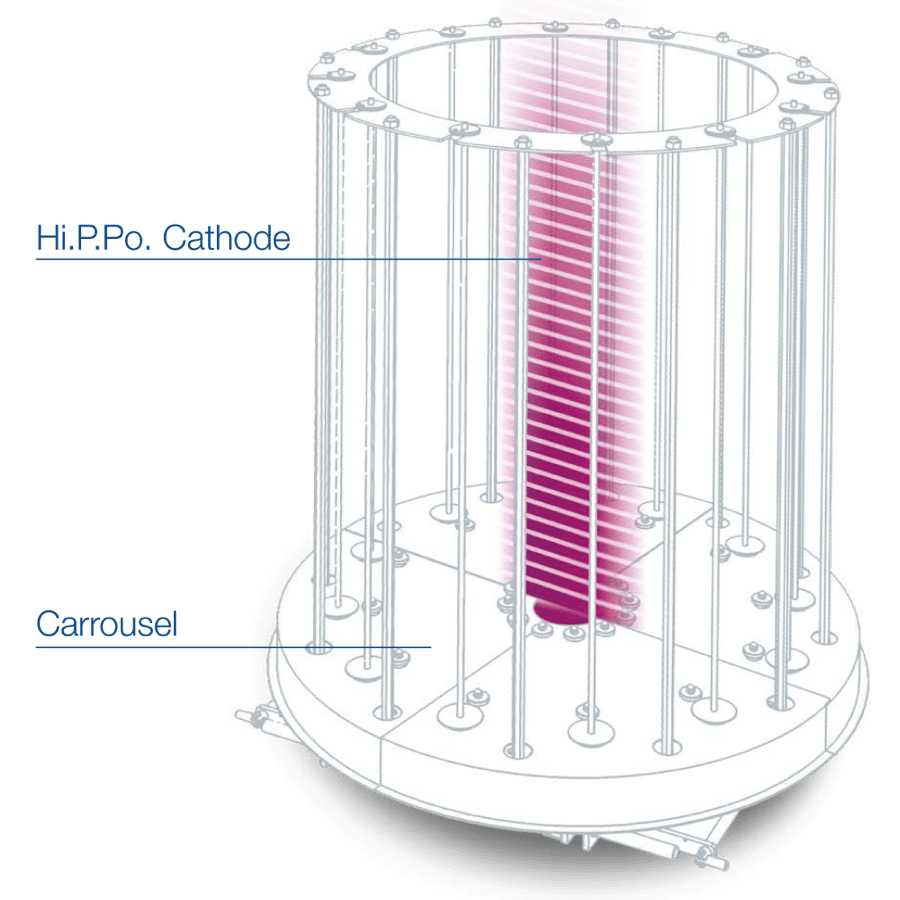

Hi.P.Po. High Productive Powered Sputtering Cathode

Kenosistec has developed and patented a new generation of Magnetron Sputtering cathodes. Hi.P.Po main feature is its high deposition rate which leads to an increase of productivity, especially if applied to production systems, ensuring, new color opportunities and guaranteeing, as well, the typical properties of a film deposited via classical sputtering.

CERTIFICATIONS

Angelantoni has introduced international quality standards in the group companies to ensure reliability and compliance with the rules, along with efficient management that is oriented towards technological innovation and process sustainability.